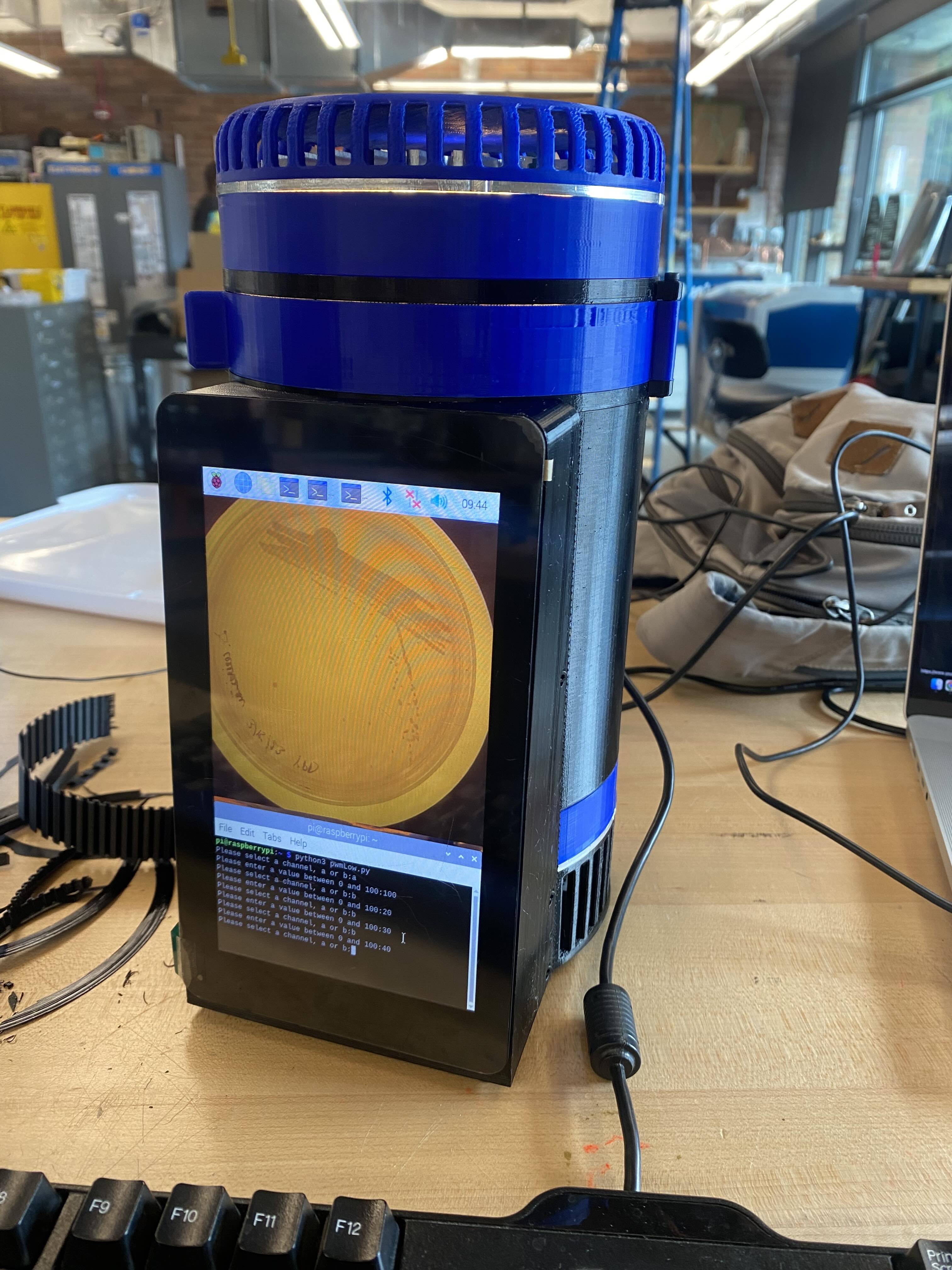

Summary: Agar plate analysis is still often performed using manual counts and informal documentation, typically captured with phone cameras or scanners. Existing automated imaging systems are expensive and frequently trade accessibility for accuracy. To explore a more open and practical alternative, I designed and prototyped a compact camera system specifically optimized for uniform illumination and reproducible agar plate imaging, enabling consistent documentation without relying on proprietary hardware.

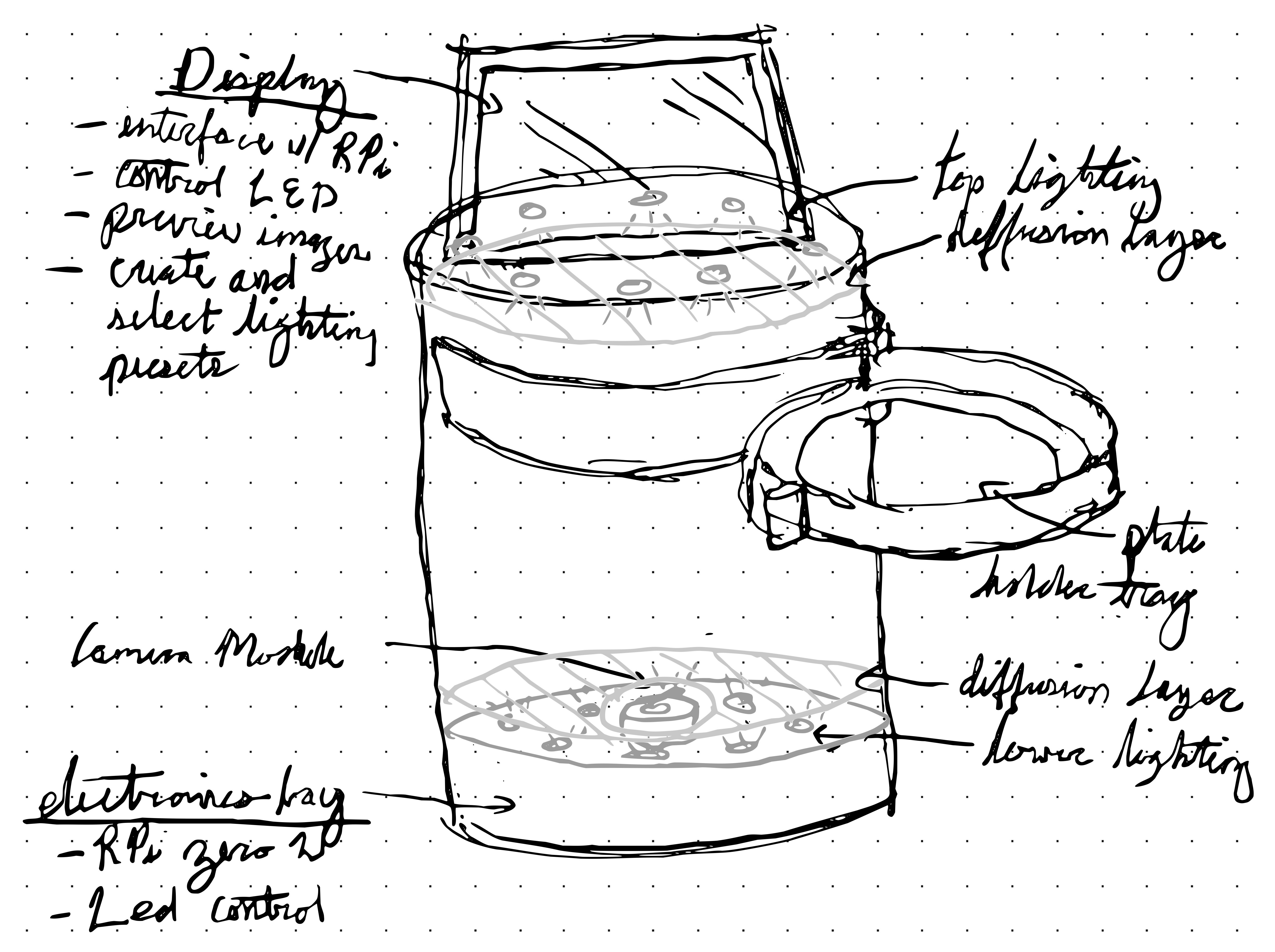

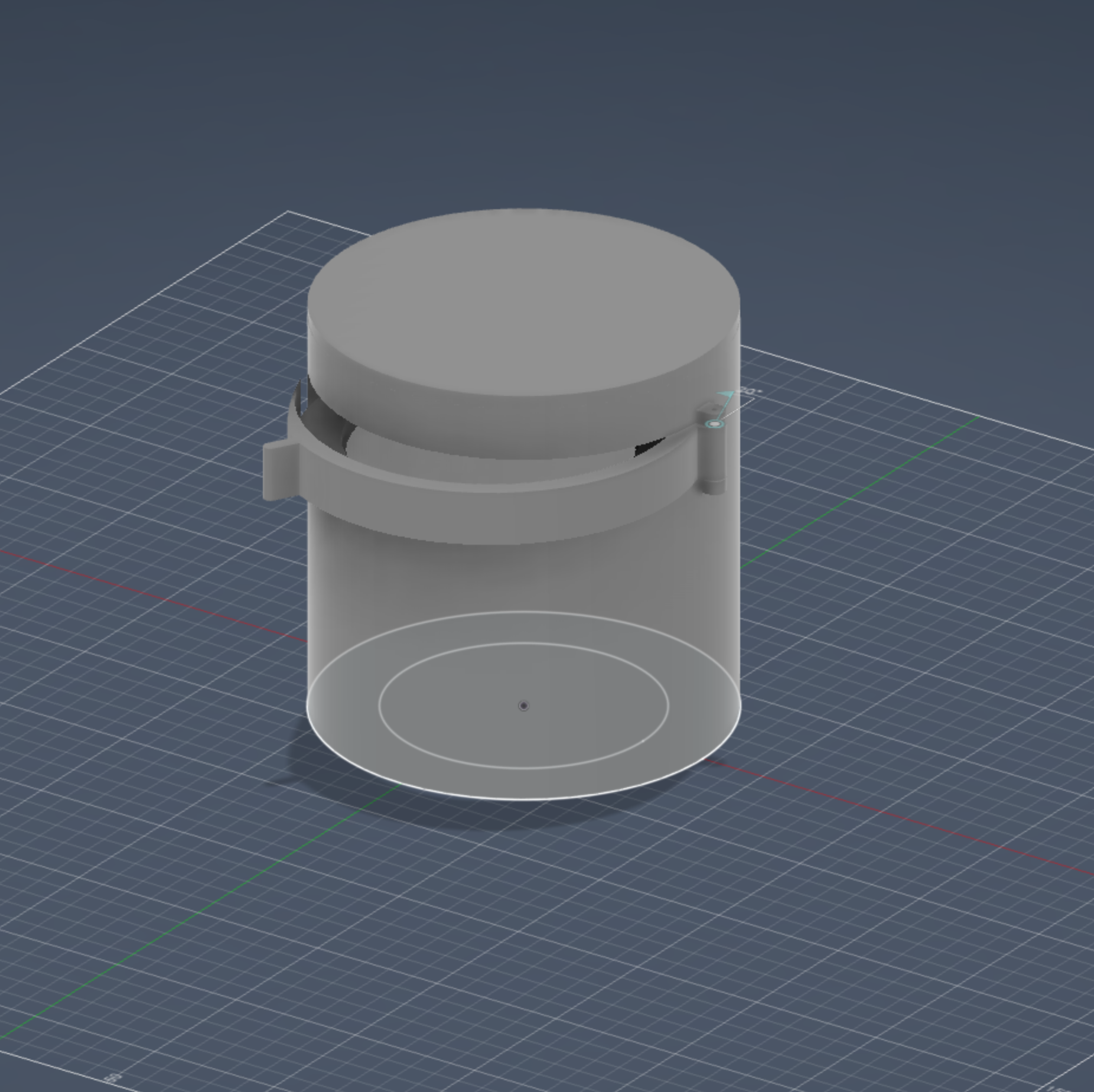

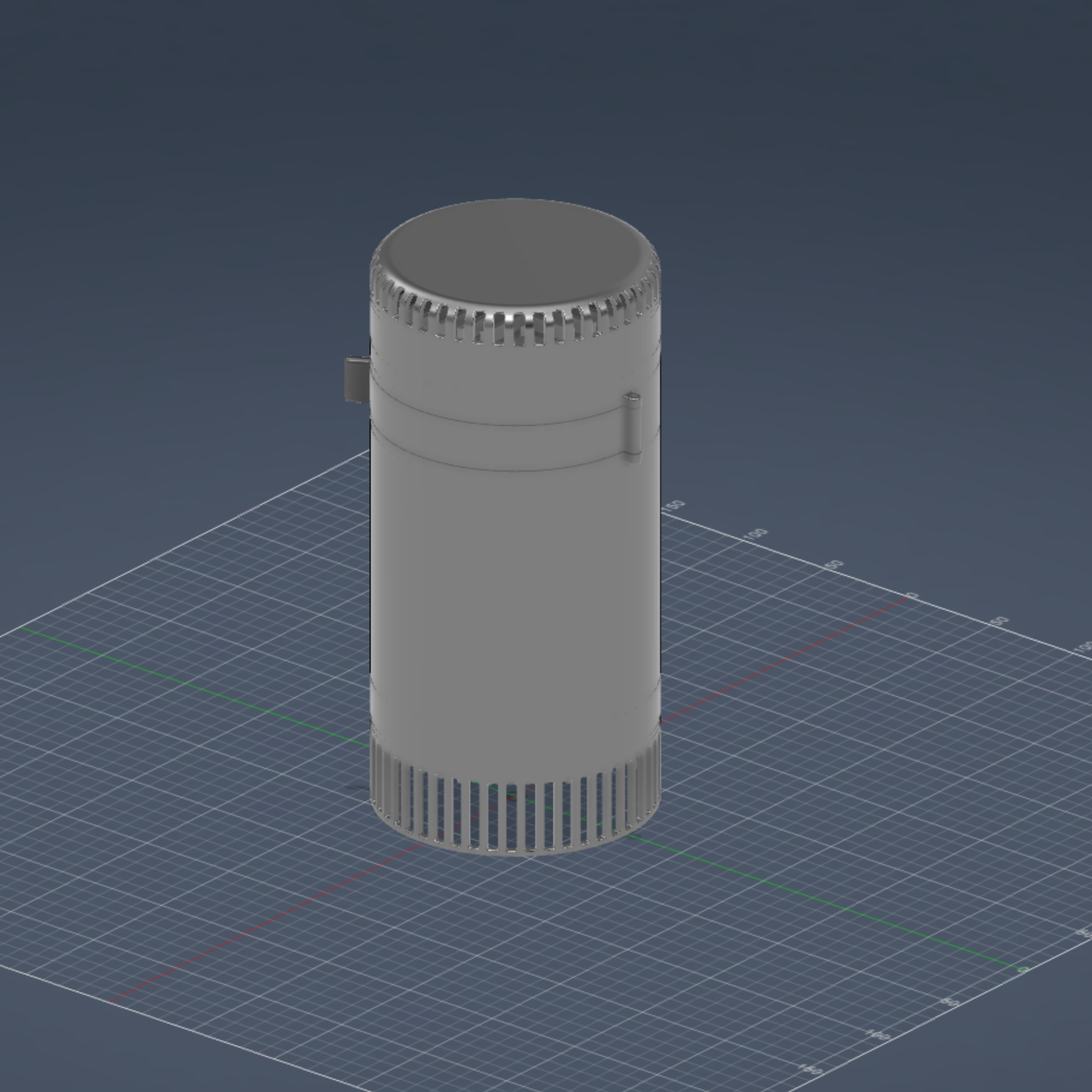

The design was centered around the most commonly used agar plate size (100 mm), which set the minimum footprint of the device. Because bench space in laboratory environments is limited, the system was designed to stack components vertically, minimizing overall footprint while maintaining functionality. The rest of the design was guided by several core goals:

To maximize accessibility, the design relied on open-source hardware and components that could be fabricated using 3D printing or basic machining available in an acadmic makerspace. The system was developed in Fusion 360 using parametric design techniques, allowing rapid iteration and easy modification across dozens of prototype versions.

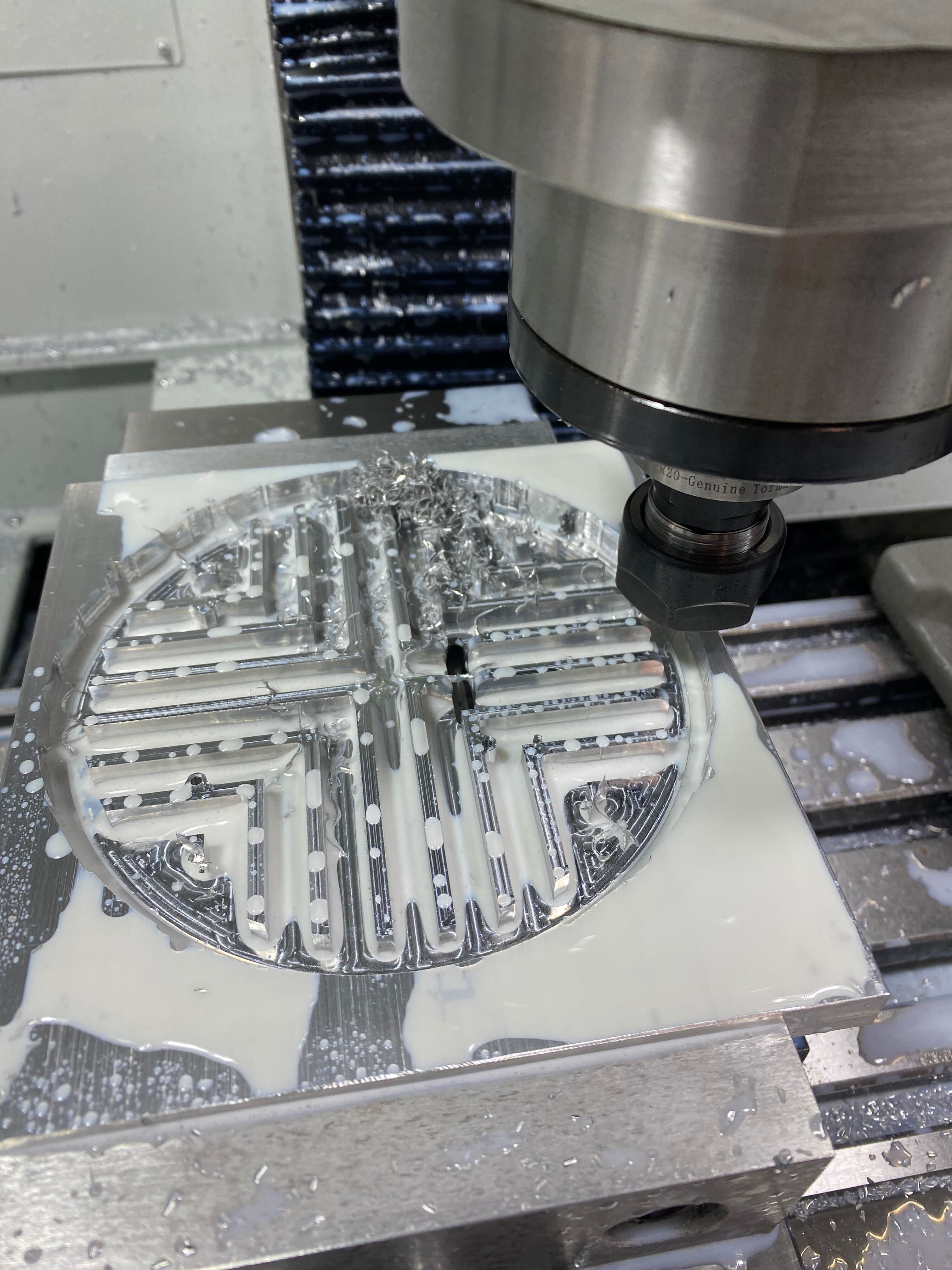

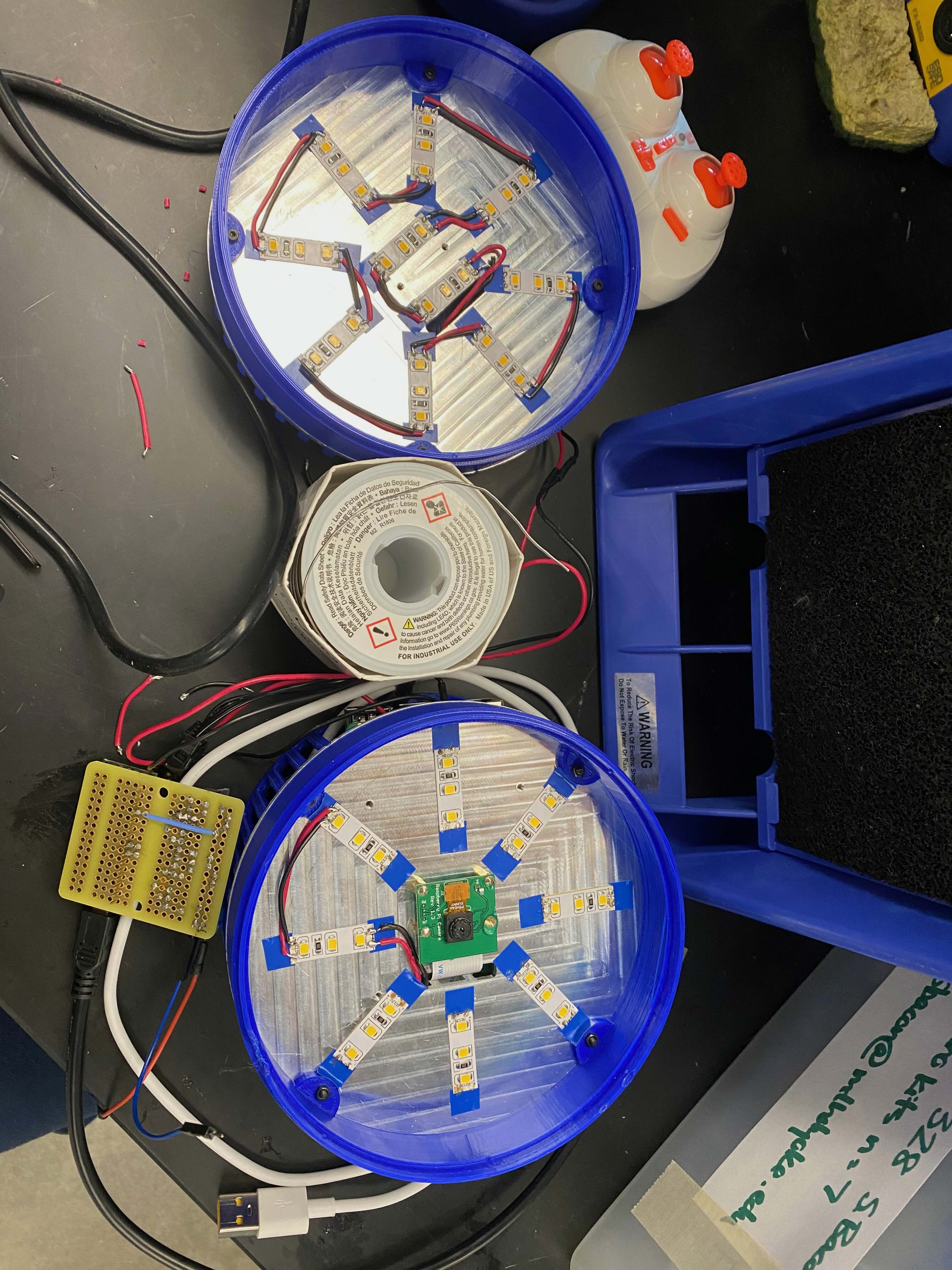

Fabrication methods were selected to support rapid iteration while remaining accessible within an academic makerspace environment. Structural components were produced using a combination of 3D printing and CNC machining, while laser cutting and vacuum forming were used to create lightweight diffusion and enclosure components. Throughout the fabrication process, early machining attempts helped identify tooling and CAM limitations, informing subsequent design revisions and manufacturing strategies. This hybrid approach enabled fast iteration without committing to a single fabrication process.

_sm_X07B6OE2iZGnX5nDFdjpT.jpeg)